Recycling waste from filament production or failed prints poses quite a challenge, albeit an interesting one. As of last year, Prusa Research has established a Sustainability department (read more about them here). But even before that, we at PrusaLab have been tinkering with various ways to deal with plastic waste in an effective and smart manner. As the company seeks to diminish its impact on the environment through life-cycle assessments of products, contractor analyses and other means, we focus on solutions that are a bit more ‘creative’. PrusaLab is a prototyping workshop after all.

One man’s trash, another man’s treasure

Before we could start making things, we had to turn our plastic waste into workable material first. Plastmakers, a Czech recycling company and a member of the Precious Plastic initiative, lent us their shredder, which allowed us to produce plastic flakes. The original idea for the usage of flakes was born in the days when PrusaLab was an open makerspace with hundreds of members. We wanted to, with help from the community, build a sheet press that could eventually be used to create plastic furniture down the road. Unfortunately, the coronavirus pandemic happened and we had to transform PrusaLab from a makerspace to a prototyping workshop. We did not want to proceed with the idea without community input, and so we scratched it and went looking for a different solution.

This is when found Plastic Guys, yet another Czech company inspired by Precious Plastic and involved in the production of recycled plastic sheets. We invited them to visit us and provided samples of pellets made from various materials. This resulted in many sheets of varying thickness and colour being pressed a few weeks later.

Let the experimenting begin!

Machining the sheets proved quite difficult at first, as plastic shavings quickly clog cutting tools. Moreover, plastic is not suitable for laser cutting due to the fumes released during the process. Eventually, we fine-tuned the cutting process on the router and decided to make something fun as our first product — how about a skateboard? After cutting the board, we used a heat gun to bend the tail, fitted it with trucks and wheels, and glued grip tape to the top. To prevent the board from cracking, we added aluminium reinforcement underneath.

The skateboard looks nice and is functional, but given its weight, it can not compare to a regular wooden board. However, we think it could be fitted with an electric motor and serve as an urban transport vehicle.

Our next experiment involved mixing plastic pellets into concrete. This created a mixture from which we cast visually intriguing jars. Their positive qualities, however, remain limited to aesthetics. These jars are mechanically less durable than if they were made from pure concrete and, as with most composites, their further recycling is very problematic, if not downright impossible.

So we came back to the idea of making original furniture from pressed plastic sheets. We made one such table by combining a welded steel construction and sheets from recycled Prusa Original MK3S parts. This table is now a centerpiece of our Prusament colleagues’ meeting room. As in the case of the skateboard, it is necessary to mention the disadvantages of sheets as a structural element. Apart from fragility and high weight, they are also more energy-intensive to produce.

Calling all robots to action

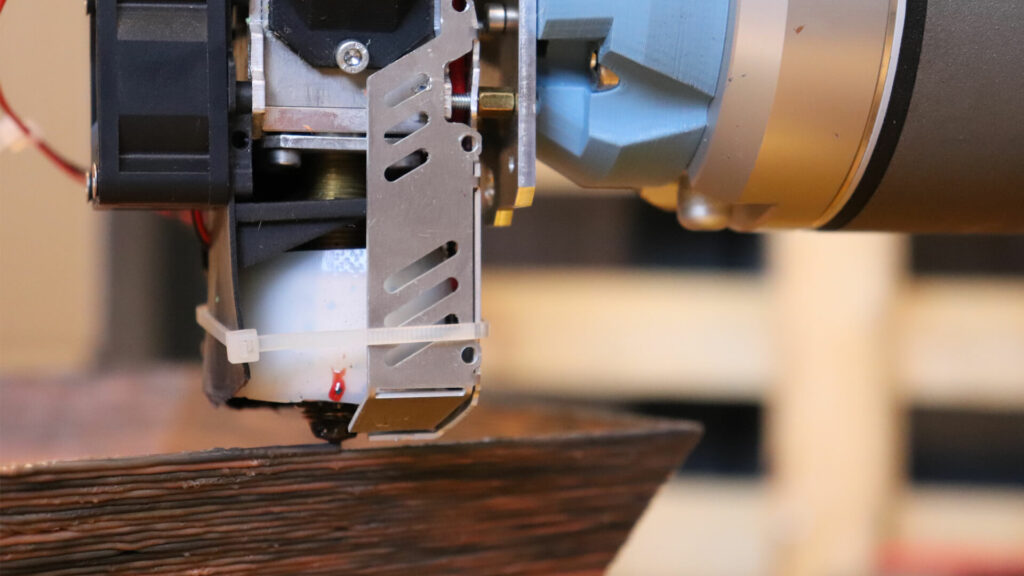

At the moment, large-format 3D printing seems to be the most interesting way of processing plastic waste for us. We are currently experimenting with different materials and exploring methods to enable 3D printing on large scale. We have acquired a robotic arm from Universal Robots and fitted it with a pellet extruder. As this is an experimental project, we are free to use and even modify products from the market for our needs. For example, the aforementioned pellet extruder has already undergone so many modifications that it has changed beyond recognition. We discuss this project in more detail in a separate article.

Thanks to the establishment of the Sustainability department at Prusa Research, we now have the support of several environmentally-oriented experts, and can therefore focus fully on the hardware side of things. After all, one of PrusaLab’s missions is to validate new technological methods in practice. This experience will hopefully carry over to other projects we are working on. And, more importantly, we’ll keep sharing everything we discover with the 3D printing community.